Researchers Design 'Green' Extraction Method for Antioxidants in Grape Skins

FAYETTEVILLE, Ark. – University of Arkansas researchers are taking grape skins left from making wine and juice and using “green” processes to extract powerful antioxidants that can be used in health products.

“The goal is to get a value-added food supplement product,” said Jerry King, professor of chemical engineering at the University of Arkansas. Beverages such as grape juice and wine contain natural antioxidants, which have anti-inflammatory properties when ingested. However, while juices and wine contain some of the antioxidants, up to 50 percent remain in the waste material left behind when the skins, stems and seeds get filtered away. “These are valuable components that don’t go into the juice or wine,” King said.

Grape waste means business: The United States generates about 15 million tons of grape waste each year, and most of it currently ends up as compost or animal feed. Extracting products with potential health benefits from the waste has commercial interest.

However, traditional extraction methods use organic solvents, which can be expensive, toxic and difficult to dispose. King and his colleague, food science professor Luke Howard, received $350,000 over four years from the U.S. Department of Agriculture as part of an interdepartmental collaboration to employ a method using pressurized water to extract the antioxidants. For the past four years, they have worked with graduate students Jeana Monrad and Keerthi Srinivas to optimize these extraction methods using a technique called subcritical water processing.

To do this, scientists heat the water under pressure, which allows it to remain liquid at high temperatures and act as an extraction solvent. They also used organic acids to isolate certain types of antioxidants.

The researchers faced several challenges with this method, because natural antioxidants can break down at high temperatures. They developed a process of continuous extraction that allows for high flow rates to minimize antioxidant degradation and maximize their breakdown.

The researchers created an extraction method that not only increases the efficiency of extraction over ethanol alone, but also produces antioxidant compounds that are smaller in size, which are more effectively adsorbed by the body.

Topics

Contacts

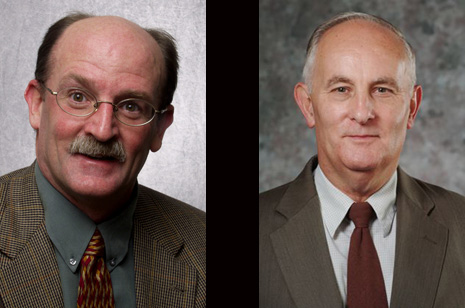

Jerry King, professor, chemical engineering

College of Engineering

479-575-3835,

jwking1@uark.edu

Luke Howard, professor, food science

Dale Bumpers College of Agricultural, Food and Lif

479-575-2978,

lukeh@uark.edu

Melissa Blouin, director of science and research communication

University Relations

479-575-3033,

blouin@uark.edu

Headlines

Honors College to Host Pulse Discussion Around Baltimore Bridge Accident

The Honors College will present a panel of faculty with expertise on engineering, labor history and supply chain to discuss the impact of the accident at 3:30 p.m. Wednesday, April 24, in Gearhart Hall, room 258.

Entrepreneurial Path Follows Tradition and Family Legacy

When Blanca Ruiz made a pivotal career decision to pursue a newfound passion rooted in a family legacy, she took advantage of training through the U of A Small Business Center.

'Peace' Sculpture by Native American Artist Dedicated at Adohi Hall

The 33-inch high bronze sculpture, created by Native American artist Retha Walden Gambaro in 1997, features a dove in two hands and titled simply "Peace," was donated by Richard Anderson and John Berry.

Cyber Careers with University SFS Alum Calvin Franz on April 25th

Alumnus Calvin Franz will be joining the CyberHogs RSO to talk about what it's like post-graduation as a cybersecurity developer in the public sector at 5 p.m. Thursday, April 25, at J.B. Hunt Center room 0216.

Take a Study Break in Mullins Library

As finals approach, the University Libraries have teamed up with partners across campus to offer study breaks in the east lobby of Mullins Library that are free and open to all U of A students.